How to Keep Clean-Burning Cookstoves From Gathering Dust: Devices that cut down on respiratory diseases too often aren’t being used

In Nana Kenieba, a backcountry village in southern Mali, cooks have well-designed, clean-burning cookstoves that they don’t use often. Instead, they cook over the open fires that the stoves were supposed to replace.

Nathan Johnson, an assistant professor of engineering at Arizona State University, and Kenneth Bryden, an associate professor of engineering at Iowa State University, visited the village four times in 2009 and 2010 to study the cooking habits of five families there. They found a tangle of reasons why cookstoves did not replace open fires.

One is that the stoves have small combustion chambers that extinguish if they are not stoked regularly, and the cooks like to leave the fires burning while they do their other work. Another is that the cooks simply used the stoves as another cooking surface to supplement their fire, the way other households might use a microwave to supplement the electric range.

From their research, Johnson and Bryden developed stove design guidelines to solve the problems that technology can solve and published them in the inaugural fall 2013 edition of “DEMAND,” a magazine about engineering for global development.

Their insights may be key to solving the crises of indoor air pollution, deforestation and economic hardship linked to open cooking fires in Mali.

But cookstoves are unused around the world. Cookstove programs have distributed the devices to 830 million people over the past 50 years, the researchers wrote in the journal “Energy” in 2012.

But, as in Mali, stoves haven’t extinguished open fires. Harvard University and MIT researchers reported no impact from stoves in a randomized study of 2,600 households in India, as published in 2012 in the journal ”Social Science Research Network.”

There may be a design solution, but not one that can be discovered in a lab. Johnson and Bryden’s work came at a high price of travel expense and time investment, so how can stove developers learn about cooks in the millions of other open-fire kitchens worldwide? And how much, if at all, are the stoves reducing air pollution and fuel consumption?

New monitoring technologies coming online now may have some answers.

Stove sensors and air testers

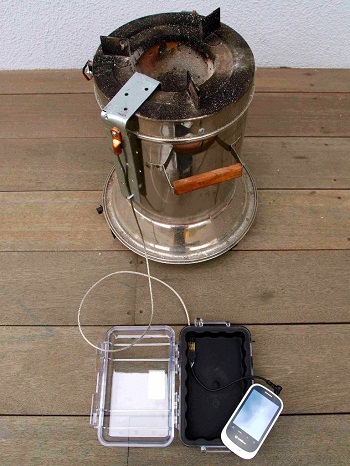

Businesses and universities are incorporating low-cost cell phone technology and high-priced proprietary instruments into stove sensors and air-quality testers. A $75 wireless device by the nonprofit technology company Nexleaf Analytics latches to the stove and records when it is in use.

It sends its data wirelessly using a cheap built-in cell phone. If you know what the stove is cooking with, the company’s analytic software can estimate the amount of fuel consumed.

(Nexleaf’s sensor, left, helps measure the usage of clean cookstoves. Source: Nexleaf Analytics)

Nexleaf can also wirelessly measure black carbon emissions around the cooking station. Wood and coal smoke carries black carbon particles that are a major greenhouse gas and a risk factor for respiratory and other diseases. Air filters can measure the quantity of black carbon in an area, but collecting the filters or mailing them into a lab for analysis can be tedious and expensive. Nexleaf Analytics has cut out the collection step with a system that analyzes cell phone photos of the filters. Snap a picture and send it to the lab and the company’s algorithms can evaluate it with nearly the same accuracy as they could if they had the filter in hand.

“We’re developing monitoring tech that works in the field. Wireless is an important piece of that. It’s very labor-intensive and difficult to visit houses and collect data. It’s also very intrusive and can change people’s cooking practices and lead to biases,” Nithya Ramanathan, founder of Nexleaf Analytics and an assistant research professor at the University of California Los Angeles, told E4C.

Nexleaf Analytic’s stove sensors are retrofits, but the company is now working to build sensors directly into stoves as they are manufactured. The goal is to reduce costs with mass production and make sensing pervasive for large-scale data collection.

Personal particle sensors

Smoky cooking fires are thought to kill 2 million people per year, according to the World Health Organization. That bird’s eye estimate doesn’t take into account the conditions of individual kitchens or the behavior of each cook. RTI International is developing wearable particle sensors to help understand how stoves and fires can affect our health. The MicroPEM, a device the size of a smartphone, measures particles in the air that are smaller than 15,000 µg / m3. Using acceleration sensors, the device also records the wearer’s movements to predict how fast they are breathing.

“Health impacts from air pollutants are not just based on the concentrations in the environment, but on how much of the pollutant is actually inhaled,” said Charles Rodes, who is leading the project. “For the first time, with MicroPEM technology, we can now estimate how much of a pollutant is actually making it into the respiratory system.”

Rodes received a $2 million grant from the Bill and Melinda Gates Foundation to develop a children’s version of the sensor. He is now working on slimming down the MicroPEM to make it suitable for children and more easily tolerated by adults. He also hopes to bring down the cost to $2,000 each.

For more information, see the the Advances in Cookstove Field Monitoring webinar by Winrock International and the U.S. Environmental Protection Agency.

Improving stove design through better data

As data comes in from the field the standards for stove design should change in response.

“We’re looking to expand into field performance. We have data that shows lab performance but we want to show that we understand the performance of these technologies in the field as well,” said Ranyee Chiang, senior technical manager at the Global Alliance for Clean Cookstoves. The alliance develops standards for stoves in an attempt to improve quality and ensure a worldwide baseline of performance. It also sets standards for performance tests themselves.

“The other component of standardization is methodology. We’re thinking about how to standardize field-testing methodologies and provide people with guidance on when to use which methods,” Chiang said.

The alliance and much of the world of engineering for global development are invested in stoves because the stakes are high. WHO has attributed 2 million deaths each year to respiratory disease from smoky indoor cook fires and traditional stoves. And expectations are soaring. The U.S. government has pledged $105 million to catalyze the adoption of cleaner stoves by 100 million households by 2020. And more than 40 countries have joined the global alliance to promote stoves that solve the problem.

If the movement is successful, it will owe a lot of its success to data-based design. Good design will integrate the device with the lifestyles of the people it serves. It will be fuel efficient, but also culturally relevant. Cooking habits vary as much as the designs of the stoves themselves. These new monitoring devices and others entering the field have the potential to change stoves and finally improve conditions in smoky kitchens worldwide.

Rob Goodier is the managing news editor at Engineering for Change.

This article originally appeared on the Engineering for Change website.

- Categories

- Education, Health Care, Technology